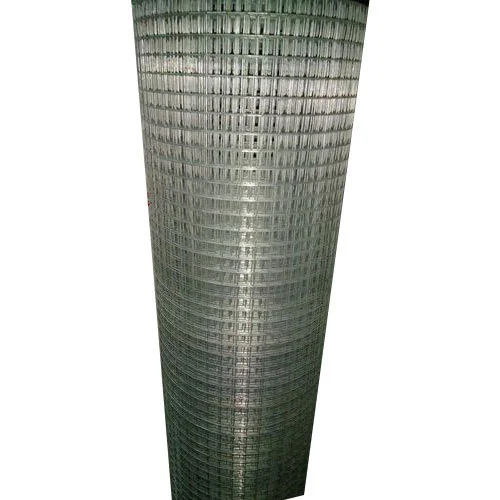

GI Welded Wire Net

GI Welded Wire Net Specification

- Aperture

- 1/2 inch to 4 inch

- Hole Shape

- Square

- Length

- 15 m - 30 m (Customized)

- Wire Gauge

- 14 to 20 SWG

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Mesh Style

- Welded Mesh

- Material

- Iron

- Alloy

- No

- Application

- Fencing, Construction, Agriculture, Industrial Usage

- Dimensions

- Standard and customized sizes

- Wire Diameter

- 0.7 mm - 2.0 mm

- Weight

- As per size and gauge

- Color

- Silver

- Galvanization Type

- GI (Galvanized Iron)

- Packing Type

- Rolls or Sheets

- Edge Type

- Straight or Folded

- Tensile Strength

- High

- Feature

- Durable, Easy to Install, Long Life

- Usage

- Security Grills, Windows, Cages, Poultry Farms

- Minimum Order Quantity

- As per requirement

- Corrosion Resistance

- Yes

GI Welded Wire Net Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About GI Welded Wire Net

GI Welded Wire Net is a type of wire mesh made from galvanized steel wires that are welded together to form a grid pattern. The wire mesh is then coated with a layer of zinc through a process known as hot-dip galvanization, which provides corrosion resistance and increases the durability of the wire mesh. GI Welded Wire Net is commonly used in a wide range of applications, including fencing, construction, agriculture, and industrial settings. It is strong, flexible, and easy to install, making it a popular choice for many different types of projects.

Specification

| Usage/Application | Industrial |

| Material Grade | G I , M.S. , S.S. |

| Surface Finishing | GI |

| Packaging Type | Roll |

| Hole Shape | Square |

| Technique | Cold Rolled |

| Wire Gauge | 18G TO 10G |

| Material | Galvanized Iron |

| Color | Silver |

| Usage | Industrial, Agricultural, Domestic, Defence |

| Size | 15MM TO 50MM |

| Wire Thickness | 18G TO 10G |

Versatile Applications Across Industries

The GI Welded Wire Net is extensively used in security grills, poultry cages, construction, and fencing. Its adaptability to various industries is enhanced by customizable dimensions, diverse aperture sizes, and availability in rolls or sheets, making it an efficient solution for both small- and large-scale needs.

Corrosion Resistance for Extended Durability

Galvanized Iron (GI) treatment ensures the mesh stands strong against rust and environmental wear, making it suitable for outdoor and humid environments. The polished finish further contributes to its resilience, supporting long service life even under demanding conditions.

Easy Installation and Reliable Safety

Designed for convenience, the welded mesh features straight or folded edges and is easy to install, reducing labor time and cost. Its high tensile strength secures sites and assets, providing dependable safety for residential, agricultural, and industrial settings.

FAQs of GI Welded Wire Net:

Q: How is the GI Welded Wire Net typically used?

A: This mesh is commonly employed for constructing security grills, cages, fencing, window barriers, and enclosures on poultry farms. Its also utilized in construction projects, agriculture, and various industrial applications due to its durability and versatility.Q: What are the benefits of galvanized iron wire mesh?

A: The main advantages include excellent corrosion resistance, high tensile strength, and a long lifespan. The GI treatment prevents rust and ensures the mesh remains robust even in harsh environments. It is also easy to install and maintain, making it cost-effective.Q: When should I choose welded wire net with higher tensile strength?

A: Selecting a welded wire net with high tensile strength is essential when you require additional security, stability, or load-bearing capacity. It is ideal for applications like fencing, industrial enclosures, construction reinforcement, and heavy-duty cages.Q: What customization options are available for size and aperture?

A: You can customize the wire meshs length (between 15m and 30m), width, aperture size (1/2 inch to 4 inch), and hole shape (square or other designs). Additionally, wire gauges range from 14 to 20 SWG, providing flexibility to suit your specific project needs.Q: How does the surface treatment benefit the wire mesh?

A: The polished surface treatment not only enhances the meshs appearance but also increases its corrosion resistance, contributing to longevity and reducing maintenance requirements.Q: Where is GI Welded Wire Net manufactured and supplied from?

A: This product is manufactured, supplied, and traded by leading companies in India, catering to domestic and export markets. They offer both standard and custom solutions as per client requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GI Wire Net Category

3mm GI Wire Net

Minimum Order Quantity : 100 Kilograms

Wire Gauge : 3mm

Application : Other, Fencing, Construction, Industrial, Animal Enclosures, Security

Dimensions : As per customer request

Color : Silver/Grey

Surface Treatment : Polished

Welded Wire Net

Minimum Order Quantity : 100 Kilograms

Wire Gauge : 12 to 22

Application : Other, Fencing, Construction, Industrial, Agriculture

Dimensions : Custom sizes available

Color : Silver/Grey

Surface Treatment : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese